You've invested time and creativity into designing the perfect 3D printed toy for your child's bath time—only to watch it crack, warp, or worse, develop hidden mould within weeks. It's a frustrating scenario that many parents and makers face when they assume all 3D printed objects can handle water exposure.

The reality is stark: most standard 3D printed toys aren't inherently water-safe without proper material selection and post-processing. Layer lines in FDM prints create microscopic gaps where water seeps in, bacteria thrives, and structural integrity weakens. Meanwhile, certain filament types absorb moisture like a sponge, degrading from the inside out. For parents concerned about hygiene and safety, these aren't minor issues—they're genuine health risks.

However, creating truly water-safe 3D printed toys isn't impossible. With the right materials, proper finishing techniques, and an understanding of which plastics genuinely withstand prolonged water exposure, you can produce durable, hygienic toys that survive countless bath times and pool sessions.

In this guide, we'll examine which 3D printing materials are genuinely water-resistant, explore essential waterproofing methods, and reveal the critical safety considerations you must address before handing any 3D printed toy to a child for water play.

Are 3D Printed Toys Safe for Water Play? A Complete Guide for Parents

Every parent faces the same dilemma: your child's favourite 3D printed toy falls into the bath, pool, or beach bucket, and you're left wondering whether it's ruined—or worse, whether it's still safe for play. With 3D printing technology becoming increasingly accessible for creating custom toys, understanding water safety isn't just about durability; it's about protecting your child's health.

Understanding Water Safety for 3D Printed Toys

The short answer: it depends entirely on the material, printing quality, and post-processing treatment. Not all 3D printed toys are created equal when it comes to water exposure.

Material Matters Most

PLA (Polylactic Acid) is the most common material for home 3D printing, but it's not inherently waterproof. PLA is biodegradable and will gradually absorb moisture, leading to weakening and potential bacterial growth in the porous layers. For bath toys or pool play, PLA poses hygiene concerns as water can seep between the printed layers, creating breeding grounds for mould and bacteria.

PETG (Polyethylene Terephthalate Glycol) offers better water resistance than PLA. It's the same material used in water bottles, making it food-safe and more suitable for water exposure. However, like all FDM (Fused Deposition Modelling) printed objects, PETG toys still have microscopic gaps between layers where moisture can accumulate.

ABS (Acrylonitrile Butadiene Styrene) is water-resistant but requires ventilation during printing due to fumes. Whilst the finished product handles water better than PLA, it's still not completely waterproof without proper sealing.

The Layer Line Problem

Here's what most people don't realise: even water-resistant materials aren't truly water-safe straight off the printer. The layer-by-layer printing process creates microscopic gaps—invisible to the naked eye but large enough for water and bacteria to penetrate. This is why professional toy manufacturers use injection moulding rather than 3D printing for water toys.

Making 3D Printed Toys Water-Safe

If you want to use 3D printed toys in water, proper sealing is essential:

Resin coating creates a waterproof barrier. Food-safe epoxy resin works well, but requires proper application—thin, even coats with complete coverage are crucial. One missed spot compromises the entire seal.

Vapor smoothing (for ABS prints) uses acetone vapour to melt and fuse the outer layers, creating a smoother, less porous surface. This method significantly improves water resistance but requires careful safety precautions.

Multiple clear coats of waterproof sealant can work for toys that won't face prolonged submersion. Apply at least three coats, allowing proper drying time between applications.

Safety Considerations Beyond Water Resistance

Water safety extends beyond just waterproofing. Consider these factors:

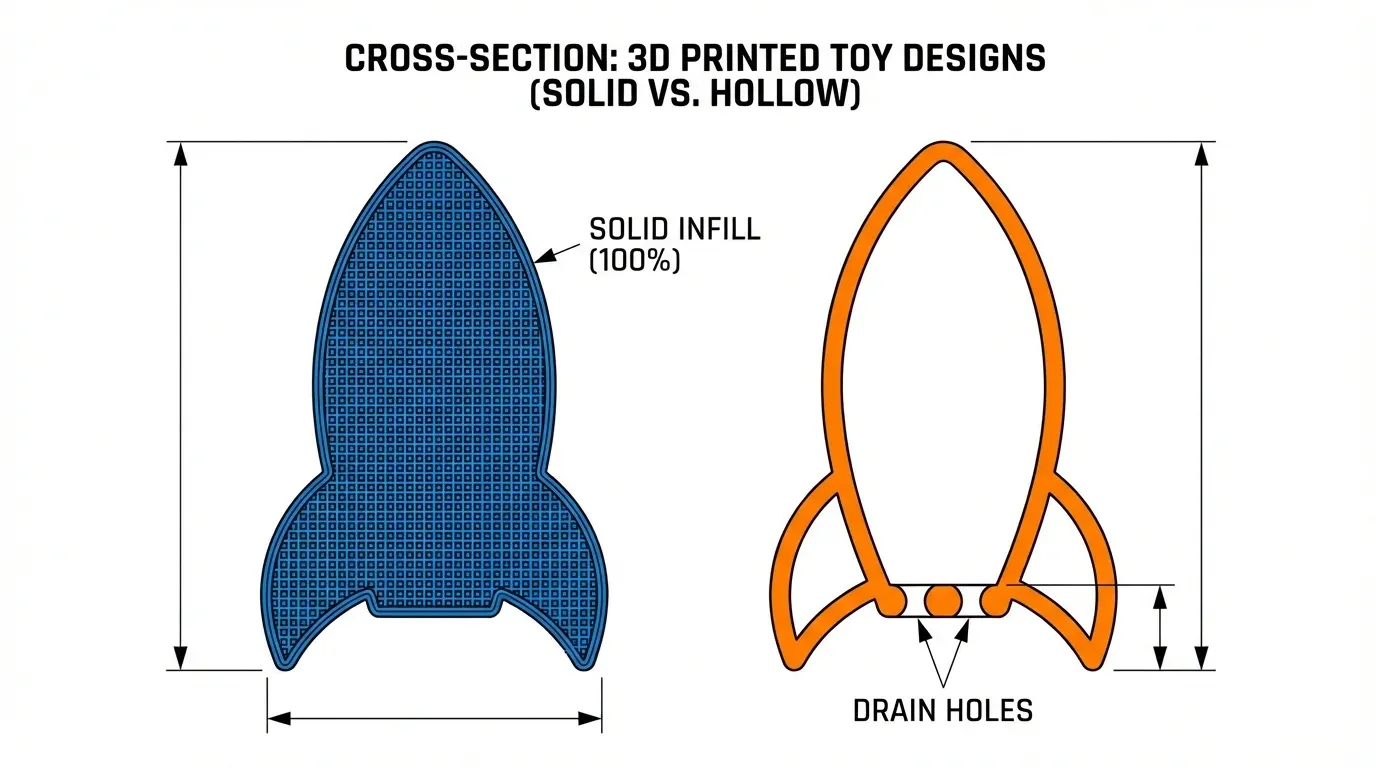

Small parts and infill patterns can trap water inside hollow toys, becoming mould factories you can't see or clean. Always print toys with either 100% infill or ensure drain holes for water escape.

Sharp edges become dangerous when wet and slippery. Sand any rough spots before sealing.

Paint and decorations may not be water-safe even if the underlying plastic is. Use only waterproof, non-toxic paints certified for children's toys.

When to Avoid Water Exposure

Some 3D printed toys should never be used in water, regardless of material. Complex mechanical parts, electronics integration, or painted details often can't withstand moisture. If a toy wasn't specifically designed and treated for water use, keep it dry.

The Verdict on Water-Safe 3D Printed Toys

Creating genuinely water-safe 3D printed toys requires more than just choosing the right filament. It demands proper sealing, regular inspection for wear, and realistic expectations about longevity. For occasional splashes, properly sealed PETG or ABS toys can work. For frequent water play, commercially manufactured water toys remain the safer, more hygienic choice.

Ready to create safer 3D printed toys? Start by selecting PETG filament, invest in quality food-safe sealant, and always test toys yourself before handing them to children. When in doubt, keep 3D printed creations as display pieces or dry-play toys—your child's safety is worth more than any custom design.

Making Water-Safe 3D Printed Toys: Your Next Steps

Creating water-safe 3D printed toys requires careful attention to material selection, post-processing techniques, and proper sealing methods. Whether you're printing bath toys for toddlers or pool accessories for older children, the fundamentals remain consistent: choose water-resistant filaments like PETG or ABS, apply appropriate sealants, and maintain smooth, non-porous surfaces.

The key takeaway? Water safety isn't just about the filament you select—it's about the entire production process. From your printer settings to your finishing techniques, each step plays a crucial role in determining whether your toys can withstand repeated water exposure without degrading or harbouring bacteria.

Remember that regular inspection and maintenance are non-negotiable. Even the most carefully sealed toys require periodic checks for cracks, delamination, or wear that could compromise their water resistance. Set a routine schedule to examine your 3D printed water toys, and don't hesitate to retire pieces that show signs of deterioration.

Ready to start creating water-safe 3D printed toys? Begin with a small test project—perhaps a simple bath toy or pool game piece. Apply the post-processing techniques we've covered, test thoroughly in water over several days, and refine your approach based on the results. Document what works for your specific printer and materials, building a reliable process you can replicate.

The future of custom, water-safe toys is in your hands—literally. With the right knowledge and careful execution, you can produce durable, safe playthings that children will enjoy for years to come.