When parents discover their child's favourite toy has snapped after just a few weeks of play, frustration sets in. It's a common scenario that raises an important question: can 3D printed toys durable enough to withstand the rigours of childhood actually exist?

The short answer is yes—but durability depends entirely on material choice, design principles, and printing techniques. Many assume 3D printed toys are inherently fragile, yet modern filaments and engineering methods produce items that rival or exceed traditionally manufactured toys in strength and longevity.

The challenge lies in understanding which materials work best for different play scenarios. A toy designed for gentle imaginative play requires different specifications than one built to survive outdoor adventures or frequent drops onto hard surfaces. Material selection, wall thickness, and infill density all play crucial roles in creating toys that last.

This guide cuts through the confusion surrounding 3D printed toy durability. You'll discover which filaments offer the best strength-to-flexibility ratios, learn design strategies that prevent common failure points, and understand real-world performance expectations. Whether you're a parent considering custom toys, a maker creating products, or simply curious about additive manufacturing capabilities, you'll gain practical insights into creating or selecting 3D printed toys that genuinely stand the test of time.

Are 3D Printed Toys Actually Durable Enough for Kids?

You've just watched your child's favourite toy shatter into pieces after a simple drop from the table. Now you're wondering: could 3D printed toys withstand the daily chaos of playtime, or are they just another fragile disappointment waiting to happen?

The answer might surprise you. Modern 3D printed toys can be remarkably durable—often outperforming their injection-moulded counterparts—but only when you understand the critical factors that determine their longevity.

What Makes 3D Printed Toys Durable

Material Selection: The Foundation of Durability

The material you choose fundamentally determines whether your 3D printed toy survives rough play or becomes landfill within days.

PLA (Polylactic Acid) works well for display pieces and gentle play but cracks under impact. It's biodegradable and safe, making it popular for educational toys, yet it struggles with outdoor use and temperature extremes.

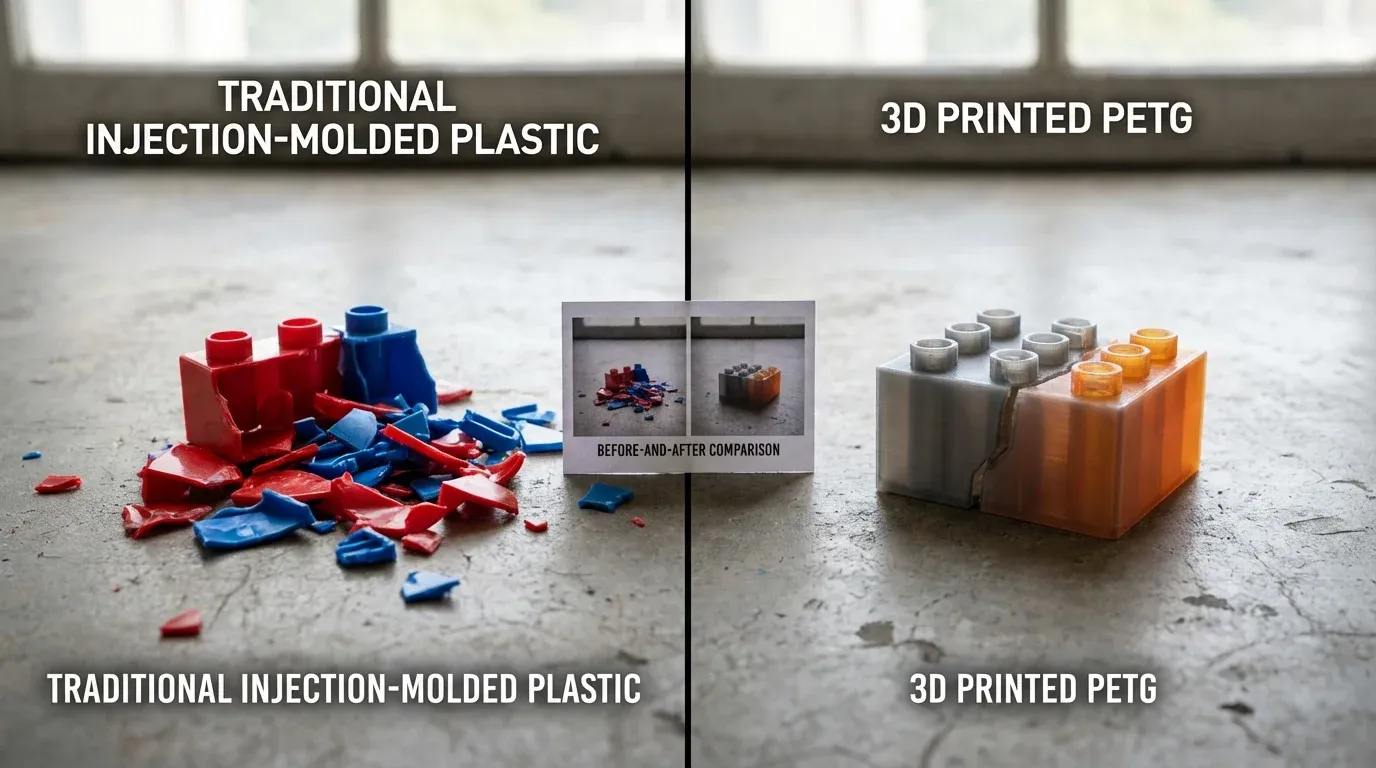

PETG (Polyethylene Terephthalate Glycol) strikes an excellent balance between strength and flexibility. It absorbs impacts without shattering, resists moisture, and maintains structural integrity across temperature ranges. For functional toys that children actually play with, PETG delivers superior performance.

TPU (Thermoplastic Polyurethane) provides rubber-like flexibility, perfect for squeezable toys, vehicle tyres, or any component requiring bend without break. However, it prints slowly and demands printer modifications.

Nylon offers exceptional strength and abrasion resistance. Professional toy manufacturers increasingly choose nylon for gears, hinges, and high-stress components, though it requires careful moisture management during printing.

%2520with%2520sample%2520prints%2520showing%2520material%2520differences.webp&w=3840&q=75)

Print Settings That Enhance Strength

Your printer settings matter as much as your material choice. A toy printed with 20% infill density crumbles under pressure, whilst 50-100% infill creates virtually solid objects that withstand considerable force.

Layer height affects both appearance and durability. Thinner layers (0.1-0.2mm) bond more effectively, creating stronger inter-layer adhesion. Thicker layers print faster but introduce weak points where stress concentrates.

Wall thickness deserves particular attention. Four to six perimeter walls create a robust shell that distributes impact forces, preventing catastrophic failure from localised stress.

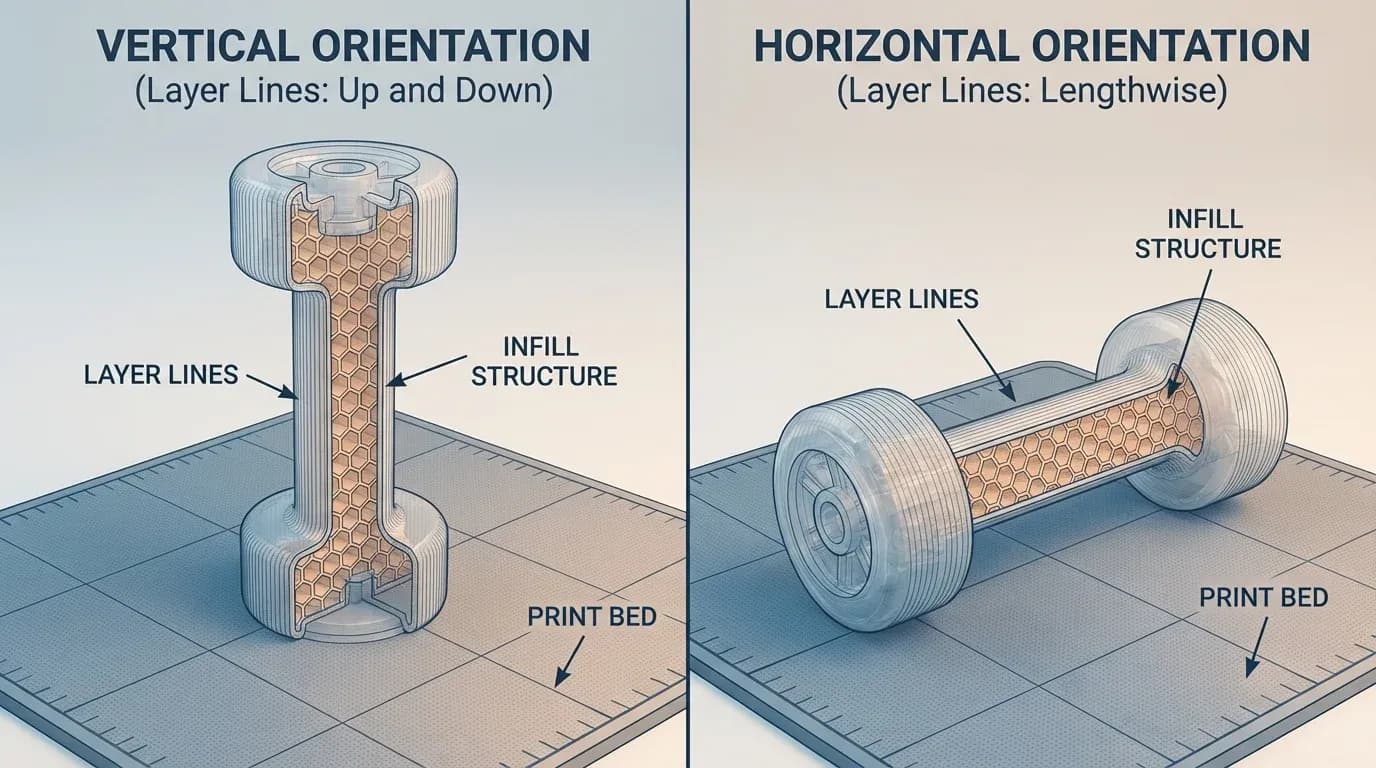

Print orientation changes everything. Position parts so layer lines run perpendicular to expected stress directions. A toy car axle printed vertically will snap; print it horizontally and it handles real-world forces.

Design Considerations for Real-World Use

Smart design compensates for material limitations. Sharp corners concentrate stress—replace them with generous fillets and radius edges. Thin sections under 2mm thickness become failure points; reinforce them or increase cross-sectional area.

Incorporate stress relief features: flexible joints, breakaway sections for safety, and rounded edges that prevent injury whilst distributing impact forces. Design with assembly in mind—multiple parts joined with snap-fits often outlast monolithic prints by allowing flex without fracture.

Comparing Durability: 3D Printed vs Traditional Toys

Real-World Performance Testing

Independent testing reveals 3D printed toys in PETG withstand drop tests from 1.5 metres repeatedly—comparable to commercial injection-moulded toys. The key difference lies in failure modes: traditional toys often shatter completely, whilst properly designed 3D printed toys crack gradually, providing warning before complete failure.

Abrasion resistance varies significantly. Nylon 3D prints actually outperform many traditional plastics in scratch resistance, whilst PLA shows visible wear within weeks of active play.

Cost-Effectiveness Over Time

A broken commercial toy means another purchase. When your 3D printed toy breaks, you print replacement parts for pennies. This repairability transforms the durability equation—a moderately durable 3D printed toy you can repair indefinitely proves more economical than an indestructible toy you cannot fix.

Practical Tips for Creating Long-Lasting 3D Printed Toys

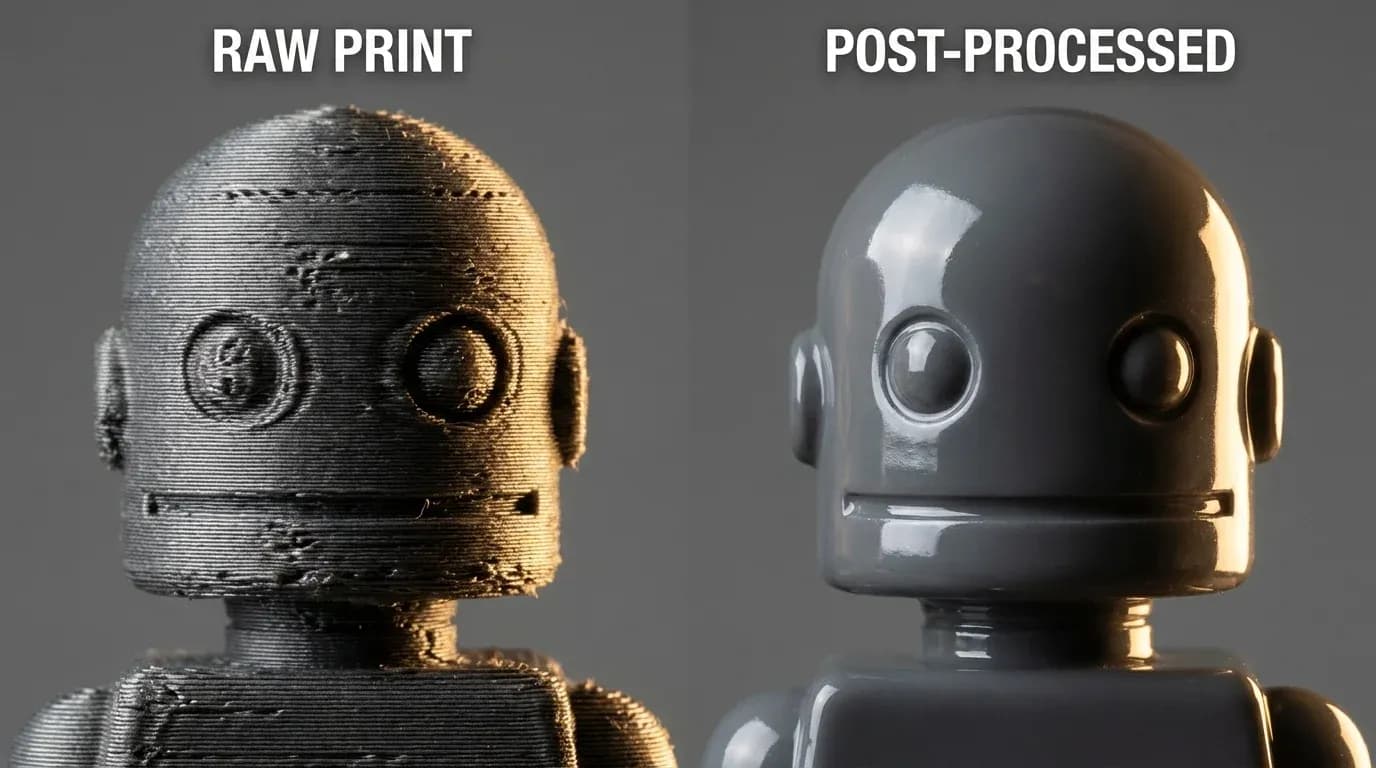

Post-processing strengthens prints. Annealing PLA in a 70°C oven for 15 minutes increases heat resistance and impact strength by 40%. Vapor smoothing with acetone (for ABS) or chemical smoothing closes surface gaps that propagate cracks.

Apply protective coatings. Food-safe epoxy resin creates a wear-resistant shell whilst sealing layer lines. UV-resistant clear coats protect outdoor toys from sun degradation.

Test before gifting. Subject prototypes to deliberate abuse—drop them, step on them, leave them in your car. Identify weak points and iterate your design. Five minutes of destructive testing saves hours of disappointment.

Scale appropriately. Smaller toys lack material volume to absorb impacts. Conversely, oversized prints develop internal stresses during cooling. Aim for palm-sized dimensions where material properties work optimally.

Ready to create durable 3D printed toys that last? Start with PETG filament, use 50% infill with four perimeter walls, and design with stress relief in mind. Your next print could outlast any shop-bought alternative—whilst costing a fraction of the price and teaching valuable engineering principles through hands-on creation.

Conclusion

The durability of 3D printed toys has evolved dramatically, transforming them from fragile prototypes into robust playthings that withstand real-world use. By selecting the right materials—whether it's impact-resistant PETG, flexible TPU, or engineered nylon—you can create toys that rival traditionally manufactured alternatives in longevity and safety.

Remember, durability isn't achieved through material choice alone. Proper design considerations, including wall thickness optimisation, strategic infill patterns, and thoughtful part orientation, play equally crucial roles in determining how well your printed toys perform over time. Post-processing techniques like annealing and coating further enhance structural integrity, extending the lifespan of your creations significantly.

The key takeaway? Durable 3D printed toys are entirely achievable when you combine appropriate materials, thoughtful design principles, and quality printing techniques. Whether you're creating educational toys for classrooms, replacement parts for beloved playthings, or custom designs for specific needs, understanding these fundamentals ensures your prints stand up to enthusiastic play.

Ready to start creating durable 3D printed toys? Begin with a single test print using PETG or ABS, implement the design principles outlined above, and observe how your toy performs under actual use conditions. Document what works and what doesn't—this iterative approach will quickly build your expertise in producing toys that last. The technology is accessible, the materials are affordable, and the potential for creating safe, durable, personalised toys has never been greater.